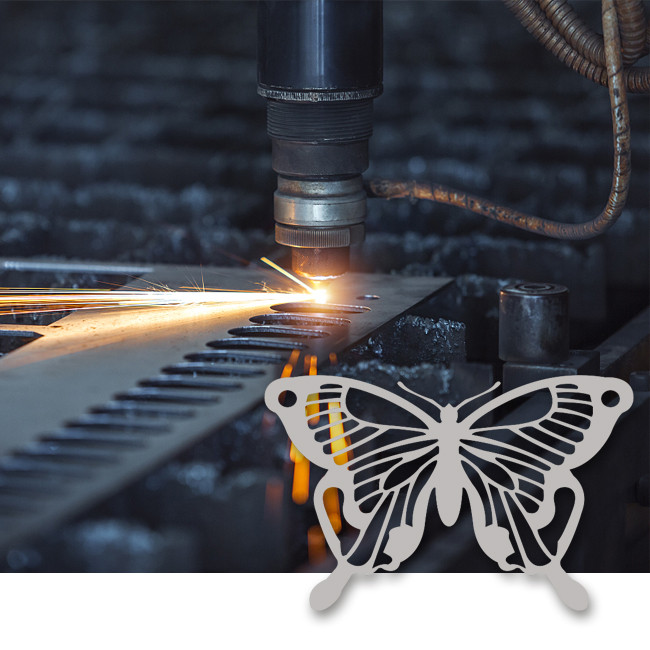

We offer CNC laser cutting of the following aluminum sheets. Achieve high-precision cutting, drilling and engraving with CO2, Nd and Nd:Yag laser cutters. And according to customer requirements, the finished parts can be sprayed, heat treated and other post-processing.

Experience the service in a few easy steps

1. Send the design file

Send us CAD design files of different parts.

2. Select the process

Here you can choose from a variety of manufacturing processes, aluminum alloy materials, and a range of surface treatments and certifications.

3. Receive the product

You will receive satisfactory sample pictures and test reports within 3 working days.

Large quantities of products within 50 tons will be completed within 20 days.

Laser cutting service advantages

Quickly produce high-precision parts within 10 days with the new laser cutting machine.

The laser cutting parts can be post-processed according to customer requirements, including spraying, heat treatment and other processes.

Our Quality Assurance department implements a strict quality assurance process.

Various tolerance options available in accordance with ISO 2768 (standard, fine) and ISO 286 (classes 8, 7, 6).

Choose from a variety of different metal sheets, varying in strength, conductivity, weight, and corrosion resistance.

Laser Cut Finish Options

Milling

Choose this finish option for the fastest delivery. Parts will leave visible tooling marks and may have sharp edges and burrs that can be removed upon customer request.

Spraying service

Surface treatment

Heat treatment

Custom made

Other processes and surface treatments are available upon customer request.

Laser cutting specifications and production capacity

Thickness range: 0-6.0mm

Standard cutting area

Sheets up to 4 mm thick: 1000×2000 mm, 1250×2500 mm, 1500×3000 mm

Thick plates over 4 mm thick: 1500×3000 mm, 2000×3000 mm, 1500×6000 mm

What is a laser?

Basic Principles of Laser Cutting

CNC laser cutting is a computer-controlled machining process that uses a high-density beam of light to cut parts from sheet metal workpieces. This process is done under the guidance of a computer according to a pre-uploaded 2D model. The laser cutting process is known for its cost-effectiveness and high precision.

Laser cutter

CO2 lasers are typically used for standard production purposes (such as cutting thinner metals)

Nd and Nd:Yag lasers are more powerful and used to cut thicker metal sheets, but are more expensive than CO2 lasers

Tolerance

Standard tolerances for most CNC laser cutters are between 0.1 and 0.2 mm, depending on size and requirements. But the tolerance level can be adjusted according to customer requirements.

Size limit

Any size; the maximum thickness of the aluminum plate does not exceed 6 mm.

DONGHENG ALUMINUM is a large-scale industrial and trade integration enterprise integrating R&D, production and sales. The company has more than 100 outstanding employees and is located in the beautiful Qingdao. Mainly engaged in the production and sales of aluminum sheets, foils and coils. The company's scale has been continuously expanded, and its sales network has covered more than 60 countries around the world. The company takes the initiative to undertake social responsibilities, and regards ecological environmental protection as the key task of development.

If you have any questions, please leave a message, we will reply as soon as possible

LET'S GET IN TOUCH AND COMMUNICATE!

We will contact you within 24 hours.